About Industrial Pasta Machines

Satellite has been importing Dry Pasta Production Lines since 2006 and having successfully installed and started over 60 Lines at leading Pasta Producers in India.

The dry Pasta Production Lines from Italy feature High Technology, Reliability and Flexibility enabling to produce besides traditional pasta shapes like Macaroni, Fusili, Vermicelli, Shell also special shapes by means of cutting devices and additional accessories. Our experience enables us to offer equipment and complete lines dedicated to a wide range of Pasta with outputs from 30 Kgs up to 1000 Kgs per hour thanks to continuous, fully automatic Extruders equipped with Centrifugal pre-mixers and vacuum extrusion devices combined with low-temperature, static drying or continuous drying systems. Some small models of Extruder and Dryer have been sold to carry out lab tests or Training and Catering Institutes, Universities as well as to medium-sized companies already producing short-cut and long pasta, in order to check the raw materials, evaluate the dough mixtures and produce new shapes leading to mass scale production.

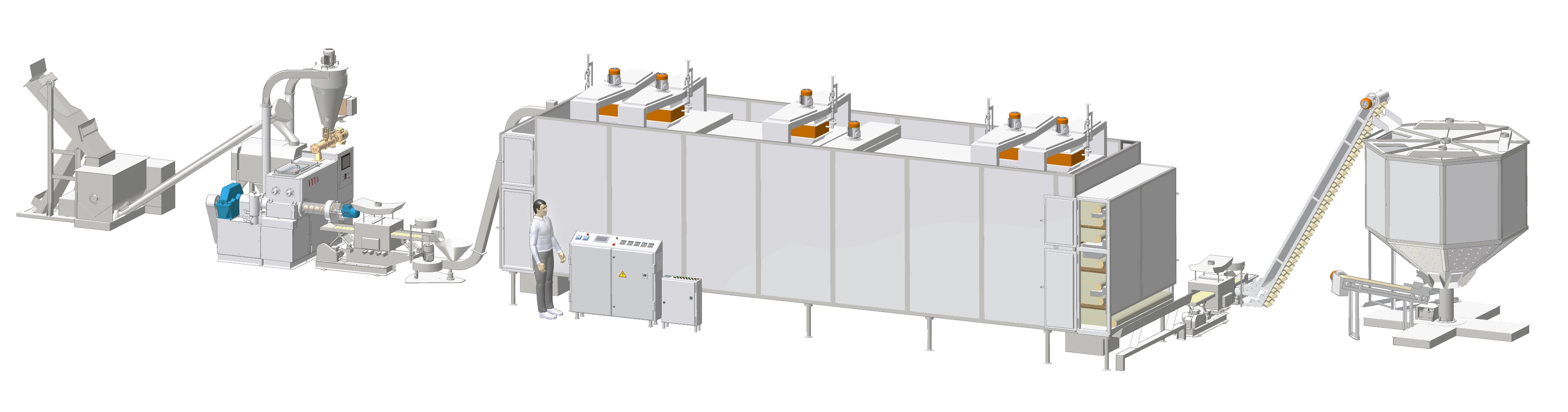

SHORT-CUT PASTA LINES UP TO 1000 KG/HR.

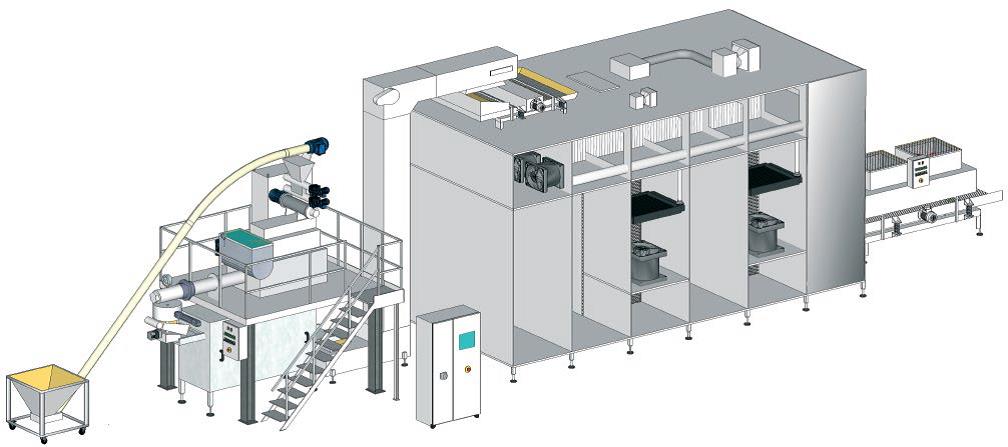

Short-cut pasta production lines can be divided into artisanal lines usually used for production of special shapes, semi-automatic lines equipped with more automation and usually used in medium, big-size pasta factories and continuous automatic lines, which are the preferred choice of Pasta Producers for large production batches. The Extruders are available in the vacuum version fitted to the extrusion bin, can be of the “batch” type, i.e. equipped with the classical mixing bin or continuous and automatic, suitable for productions above 100 Kgs per hour. In this case they are equipped with automatic dosing feeders for flour and water and Centrifuged pre-mixer. After the mixing phase the dough is extruded through the pasta die which determines its shape. At exit of the die the pasta is cut at the desired length by means of cutter with variable speed controller and transferred to the Pre-dryer fitted with vibrating tiers for the initial pre-drying phase, which is needed to stabilize the product shape and extract some 5% of its humidity. Drying can be effected on carriages (trolleys) in static chambers or in continuous form on Conveyor Belt. Static drying means that the product is homogeneously spread onto trays that are stacked on a trolley. Continuous drying is suggested for long production cycles. In this case the pasta is taken from the Pre-dryer and transferred to the belt by means of an Elevator (buckets) into the Dryer; at the exit of the continuous dryer the pasta will be fully dried and stabilized and ready for Packaging.

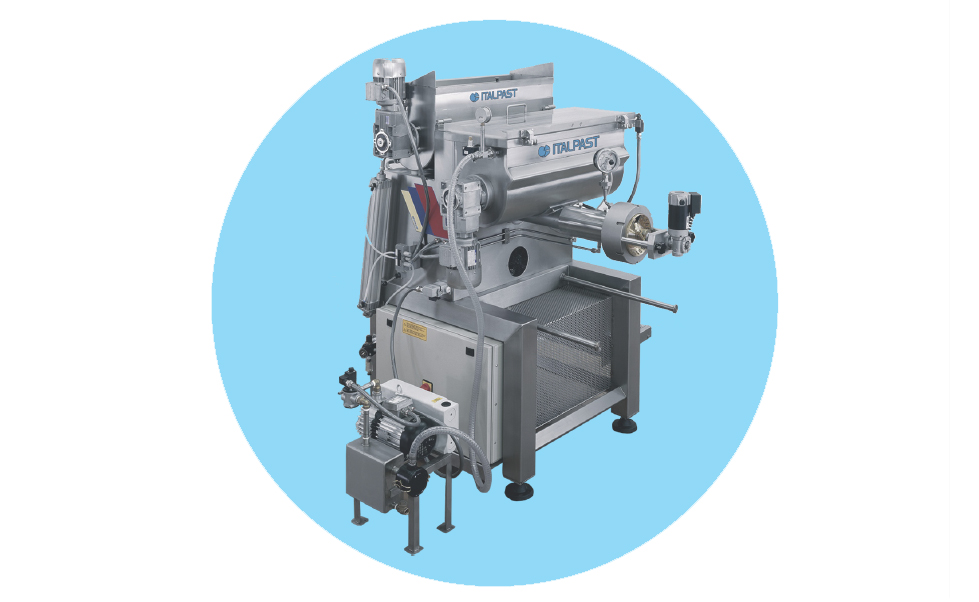

EXTRUDER

Automatic Continuous Line for Short Cut Pasta featuring output from 300 up to 1000 Kg/Hr.

The Automatic Continuous Lines for the production and drying of short-cut pasta from 300 upto 1000 Kg/Hr have been designed and manufactured to meet all the pasta producer’s requirements for easy operation, simplicity and quality of the Pasta. We offer a very economical solution of quality vis-à-vis economy in production. This is backed by our popular After Sales Service.

Technical and technological specs of the machines making up the line:

- Single-screw Extruder: Equipped with centrifugal mixer and vacuum mixer for feeding and mixing of the flour and water.

- Pre-dryer by vibrating: Stainless steel structure, continuous belt and insulated paneling that can easily be opened and cleaned. Heating system by finned heat exchangers running either by hot or overheated water, served by axial electro-ventilators suitable for treatment temperature up to 85.C.

DRYER

Continuous Dryer

Featuring Belts in thermo-resistant, polyester mesh made up of two technically superior design equipped with independent climate control probes: pre-drying, drying and stabilization areas. The paneling that can be fully opened all along the machine perimeter. The Dryer is made up of AISI 304 stainless steel panels with internal insulation by 20mmrock wool and injection of high-density polyurethane thus totaling 60mm total thickness. The Belts in thermo-resistant, polyester mesh of 1700mm width supported by stainless steel bars and chains equipped with independent, variable-speed gear motor that is controlled by the inverter from the main line control panel. The loading and distribution device of the product onto the drying belt is made up of a light metal structure and stainless mesh driven by eccentric mass motor-vibrators by adjustable intensity. The heating groups are made of winged exchangers running either by hot or overheated water, served by axial electro-ventilators suitable for high temperatures. The air exchange group is made by inlet and exhaust piping and proportional opening valve that is fully made in stainless steel.

Ambient Air Cooler

Served by high-performance axial fans or upon demand by Freon evaporators or glycol water running exchangers. Transport of the product is effected on polyester belt driven by variable speed, independent gear motor.

Electric Control Panel

Equipped with PLC and color touch screen, enabling software integration with PC controlled, supervision system.

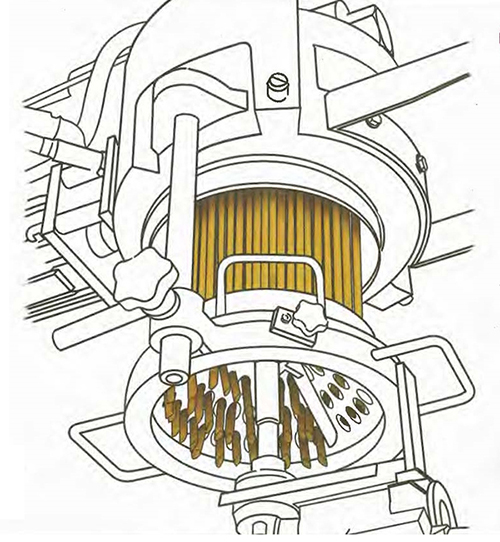

PASTA DIES

In view of the population of the Pasta Machine on the increase in India we stock Dies for popular Pasta shapes. We also stock Inserts for the Pasta Dies that we have supplied to our customers. Our Inserts and Dies are made from high quality Bronze Material with option for Teflon and also chrome plated surface for longer life. The dies are imported from one of the best Pasta Die Manufacturers in Italy.

We also supply the Penne Die with Angular cut which has recently become popular in the Indian Market. Along with the Pasta Dies and Inserts we also stock and supply Filters and Cutting Blades of different dimensions. Your single source of Dies and Accessories is now at your door step.

We can suggest the ideal solution according to the type of Extruder and output desired by you. We can also offer special shape Dies for production of Fryum and 2D Expansion Snack products.

Precision, accuracy and workmanship is our Motto.